In the rapidly evolving landscape of global manufacturing and digital commerce, the bridge between a conceptual idea and a market-ready product has never been shorter, yet the technical requirements to cross that bridge have never been more complex. Today, 3D modeling and design sit at the heart of industrial innovation. From the chair you are sitting on to the smartphone in your hand, every modern object begins its life in a three-dimensional digital environment.

However, as the demand for high-fidelity visuals, 3D Rendering, and immersive experiences like Augmented Reality – Virtual Reality grows, many companies find themselves at a crossroads: should they build an expensive in-house design department or leverage global expertise?

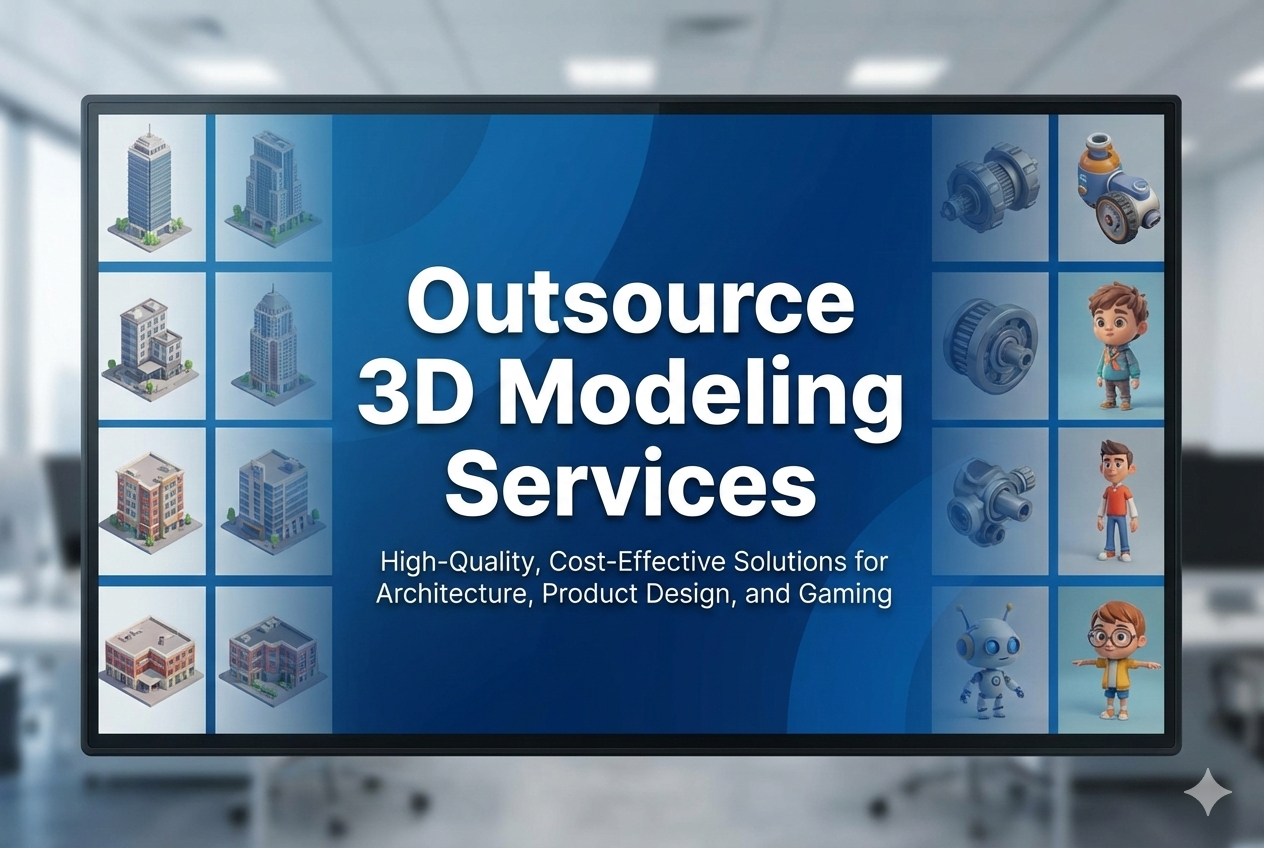

Choosing to outsource 3D Modeling services has shifted from being a mere cost-cutting measure to a strategic powerhouse for modern product workflows. In this comprehensive exploration, we will dive deep into how outsourcing transforms product development, specifically focusing on furniture, architecture, and the burgeoning world of AR/VR.

Why 3D Modeling and Design is the New Standard

Traditionally, product development was a linear, siloed process. Designers created blueprints, engineers built prototypes, and marketers photographed the finished product. Today, 3D modeling and design has collapsed these silos. A single 3D asset now serves as the “digital twin” of a product, used for stress testing, aesthetic refinement, and consumer-facing content long before a physical item exists.

The Speed of Innovation

Outsourcing allows firms to bypass the “hiring bottleneck.” Instead of spending months recruiting and training in-house artists, businesses can immediately tap into a global pool of talent proficient in the latest software suites. This agility ensures that the product workflow remains fluid, allowing for rapid iterations that keep pace with market trends.

1. The Evolution of Product Workflows: From 2D Drafts to Digital Twins

Traditionally, product design was a linear, time-consuming process involving 2D sketches, physical prototyping, and constant back-and-forth between engineers and manufacturers. Modern workflows have ditched this “analog” approach for a digital-first methodology.

By utilizing 3D Product Design, companies can create a “Digital Twin” of their product before a single piece of raw material is cut. When you outsource these services, you gain access to specialists who understand the nuances of geometry, topology, and mechanical integrity. This digital-first approach allows for:

- Rapid Iteration: Changes that used to take weeks in physical prototyping now take hours in a 3D environment.

- Error Reduction: 3D models allow for interference checking and stress testing in a virtual space.

- Stakeholder Alignment: It is much easier for a client to approve a photorealistic 3D model than a technical blueprint.

2. Transforming the Furniture Industry: Why Outsource 3D Furniture Modeling?

The furniture industry has perhaps seen the most significant disruption through 3D technology. E-commerce giants like IKEA and Wayfair have set a high bar, where customers expect to see a sofa from every angle, in every fabric, and even in their own living room via a phone screen.

The Power of Granular Detail

When a brand decides to outsource 3D Furniture Modeling, they aren’t just getting a shape; they are getting a digital asset that includes:

- Texturing: The ability to see the weave of a fabric, the grain of the wood, or the reflection of polished chrome.

- Soft Body Dynamics: Realism in how a cushion “sinks” or how leather creases, which is vital for consumer trust.

Efficiency in Cataloging

For furniture manufacturers, creating physical prototypes for an entire yearly collection in five different colors is prohibitively expensive. Outsourcing allows for the creation of one master model that can be rendered in infinite variations. This “virtual photoshoot” approach is significantly cheaper and faster than traditional photography.

3. The Technical Pillars: 3D Rendering and Texturing

The “magic” of 3D modeling lies in its presentation. A raw 3D mesh is just a collection of points and lines. To make it sellable, you need 3D Rendering and Texturing.

Professional Texturing

Texturing is the process of wrapping a 2D image around a 3D object to give it color and surface detail. Professionals at Outsource 3D Modeling use PBR (Physically Based Rendering) workflows to ensure that materials react to light exactly as they would in the real world. Whether it’s the brushed aluminum of a laptop or the velvet of a headboard, precision texturing is what bridges the gap between “fake” and “real.”

High-End Rendering

3D Rendering is the final step where the computer calculates light, shadows, and reflections to produce a still image or animation. Outsourcing this task is beneficial because high-end rendering requires massive computing power (Render Farms). By outsourcing, businesses save on hardware costs while receiving cinema-quality visuals for their marketing campaigns.

4. Bridging Architecture and Product Design

The line between 3D Architecture and product design is blurring. In modern workflows, architects don’t just design shells; they design experiences. This requires highly detailed internal assets.

When developers outsource 3D Modeling services, they often require assets for “Architectural Visualization” (ArchViz). This involves placing realistic 3D furniture and products into a 3D architectural environment. This holistic approach helps real estate developers sell properties before the foundation is even poured. It allows potential buyers to walk through a digital version of their future home, complete with realistic lighting and furniture.

5. The New Frontier: Augmented Reality – Virtual Reality (AR/VR)

We are entering the era of “Spatial Computing.” Augmented Reality – Virtual Reality is no longer a gimmick; it is a vital sales tool.

- Augmented Reality (AR): Allows customers to place a 3D model of a product in their actual environment using a smartphone.

- Virtual Reality (VR): Allows for fully immersive training simulations or virtual showrooms.

However, AR/VR models have strict technical requirements. They must be “low-poly” to run smoothly on mobile devices but “high-detail” enough to look good. This is a delicate balancing act. By choosing to outsource 3D Modeling services, companies can ensure their models are optimized for these platforms. Expert modelers know how to bake high-resolution details onto low-resolution meshes, ensuring a seamless user experience without lag.

6. Strategic Advantages of Outsourcing the Workflow

Why is outsourcing becoming the standard for 3D Product Design?

- Access to Global Talent: You are no longer limited to the talent in your local zip code. You can hire specialists in organic modeling, hard-surface modeling, or lighting.

- Scalability: If you have a product launch with 500 items, you can scale your outsourced team up instantly. Once the project is done, you don’t have the overhead of a large permanent staff.

- Focus on Core Competencies: A furniture designer should focus on design and ergonomics, not on the technicalities of “UV unwrapping” or “Retopology.” Outsourcing allows your core team to innovate while the technical execution is handled by experts.

- 24/7 Productivity: By utilizing different time zones, a project can be worked on around the clock, significantly shortening the “Time-to-Market.”

7. The Future: AI and Automated 3D Workflows

As we look forward, the integration of AI in 3D modeling and design is inevitable. However, AI still struggles with the precision required for manufacturing and high-end aesthetics. The current “gold standard” workflow involves human experts using AI tools to speed up repetitive tasks like UV mapping or basic retopology, while maintaining human oversight for artistic direction and structural integrity.

Outsourcing partners are usually the first to adopt these high-end technologies, ensuring that their clients always stay ahead of the curve without having to constantly reinvest in new software licenses and training.

Conclusion

The impact of outsourcing 3D Modeling & Design on modern product workflows is transformative. It levels the playing field, allowing small startups to compete with global corporations by providing access to world-class 3D Rendering, precise Texturing, and cutting-edge Augmented Reality – Virtual Reality models.

Whether you are looking for 3D Architecture visualization, detailed 3D Furniture Modeling, or comprehensive 3D Product Design, the move toward outsourcing is a move toward efficiency, quality, and innovation. As the digital world becomes more immersive, the quality of your 3D assets will become your brand’s most valuable currency.

As we look toward a future dominated by digital twins and the metaverse, the ability to produce world-class 3D product design and 3D furniture modeling will be the deciding factor in brand longevity. By choosing a specialized partner like Outsource 3D Modeling, businesses aren’t just cutting costs—they are expanding their creative horizons.

For businesses ready to elevate their digital presence, Outsource 3D Modeling offers the expertise and scalability required to thrive in the modern market.

Frequently Asked Questions (FAQs)

1. What are the primary benefits when I outsource 3D modeling services?

Outsourcing provides access to global expertise, reduces overhead costs associated with software and hardware, and significantly speeds up production timelines. It allows your core team to focus on strategy while experts handle the technical execution of 3D modeling and design.

2. How does 3D furniture modeling help in e-commerce?

When you outsource 3D furniture modeling, you create digital assets that allow customers to visualize products in their own space via AR. It also enables “virtual photography,” where you can generate images of furniture in various colors and settings without ever manufacturing a physical prototype.

3. What is the difference between 3D modeling and 3D rendering?

3D modeling is the process of creating the mathematical “shell” or wireframe of an object. 3D rendering is the final step where lighting, texturing, and camera angles are applied to create a realistic 2D image or animation of that model.

4. Can outsourced 3D models be used for Augmented Reality (AR)?

Yes. Specialized outsourcing firms create “AR-ready” models. These are optimized for performance to ensure they load quickly on mobile devices while maintaining the high-quality detail required for Augmented Reality – Virtual Reality applications.

5. Why is texturing important in 3D product design?

Texturing adds realism. Without it, a 3D model looks like a plastic toy. Professional texturing simulates real-world materials like metal, glass, or fabric, which is essential for convincing customers of a product’s quality during the 3D product design phase.

6. How does 3D architecture overlap with product modeling?

3D architecture provides the environment where products live. Many businesses outsource both to ensure that their products (like lighting fixtures or furniture) are perfectly integrated into architectural visualizations, providing a holistic view for developers and interior designers.